Blog

When managing a commercial property in Rochester, NY, choosing the right roofing system can have a long-term impact on your building’s performance, energy efficiency, and overall operating costs. Two of the most common flat roofing options — TPO (Thermoplastic Polyolefin) and EPDM (Ethylene Propylene Diene Monomer) — are both proven systems, but they perform differently depending on weather conditions and building needs.

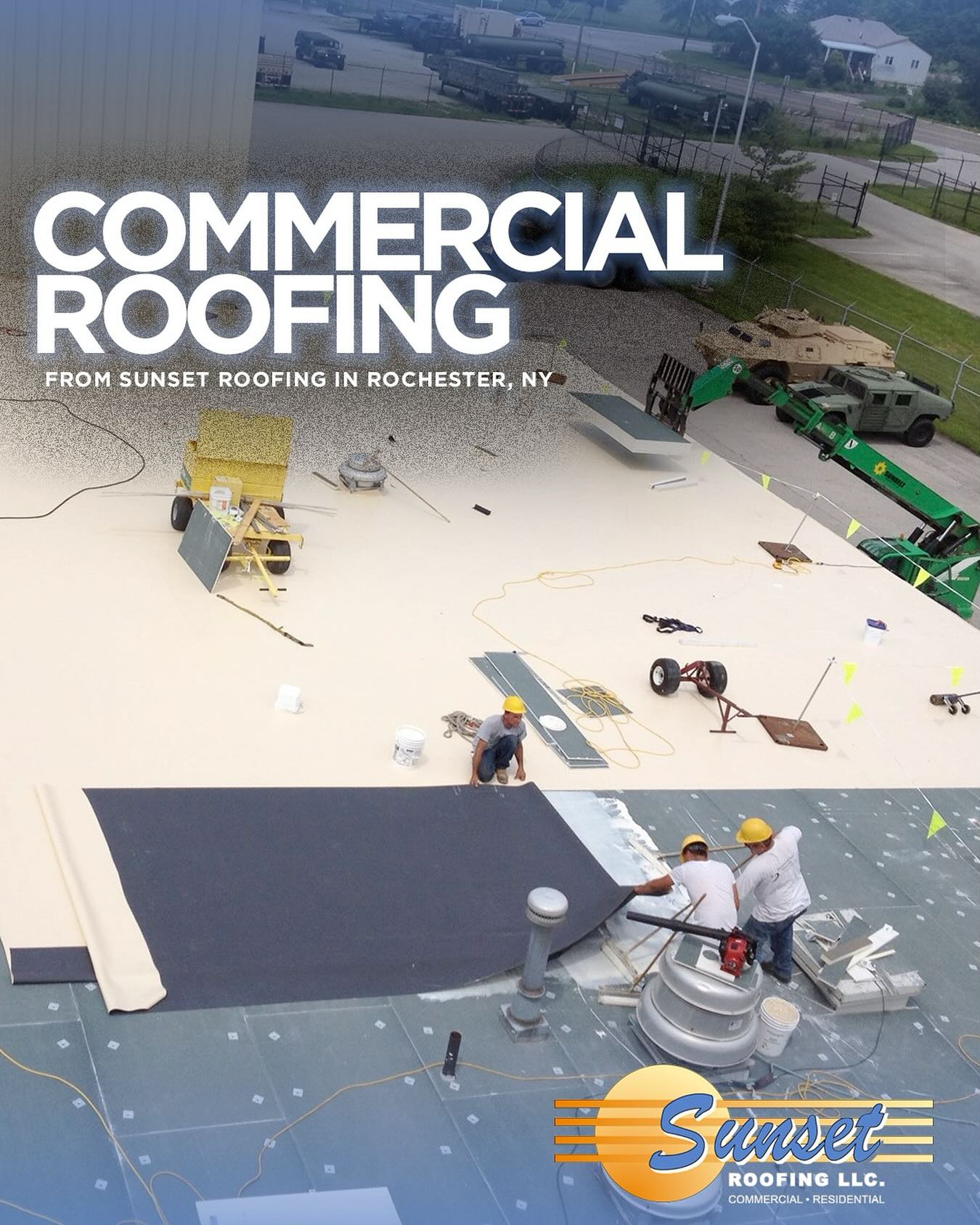

At Sunset Roofing, we’ve installed both TPO and EPDM roofs across Western New York. Here’s a detailed look at how each system stands up to our challenging climate — and how to choose the right one for your business.

Understanding the Two Systems

EPDM Roofing: Often called “rubber roofing,” EPDM is a synthetic membrane that’s been trusted for decades. It’s known for its flexibility, durability, and ability to withstand extreme temperatures. EPDM membranes are typically black, which helps them absorb heat during cold Rochester winters, though white-coated versions are also available.

TPO Roofing: A newer technology, TPO is a thermoplastic membrane designed for superior reflectivity and energy efficiency. It’s most commonly installed in white or light colors to reflect sunlight, which helps lower cooling costs during summer. TPO membranes are hot-air welded at the seams, creating a watertight and durable bond that resists leaks when installed correctly.

TPO vs. EPDM: Side-by-Side Comparison

| Feature | EPDM Roofing | TPO Roofing |

|---|---|---|

| Material Composition | Synthetic rubber membrane, available in 45, 60, or 90 mil thicknesses. | Thermoplastic membrane made from polypropylene and ethylene-propylene rubber blend. |

| Typical Color | Black (absorbs heat) or white-coated (reflective). | White or light-colored for maximum reflectivity. |

| Cold-Weather Performance | Excellent flexibility in freezing temperatures and superior resistance to cracking. | Performs well in cold climates when seams are properly welded and maintained. |

| Seam Construction | Adhesive or taped seams; easier to repair but can degrade over time. | Heat-welded seams create a single watertight bond that resists leaks. |

| UV & Weather Resistance | Highly resistant to ozone, UV, and extreme weather exposure. | Excellent UV and chemical resistance when properly formulated. |

| Energy Efficiency | Absorbs sunlight, helping reduce heating costs in cold climates. | Reflects sunlight, lowering cooling costs in warm months. |

| Installation | Simpler and more forgiving; ideal for retrofit or older roofs. | Requires precise heat-welded installation by trained technicians. |

| Lifespan | 25–30+ years with proper maintenance. | 20–25 years depending on manufacturer and upkeep. |

| Cost | Generally lower material and labor cost. | Slightly higher upfront cost due to welding requirements. |

| Maintenance | Easier to patch and reseal using adhesives or tape. | Requires specialized equipment for repairs and seam re-welding. |

How Rochester’s Climate Influences Roof Performance

Rochester experiences all four seasons — often in the same week. That means your commercial roof must endure heavy snow, ice, wind, rain, and UV exposure. The city’s freeze-thaw cycles and lake-effect snowfall create unique stress points for flat roof systems. Let’s look at how TPO and EPDM handle these conditions:

- Cold Resistance: EPDM’s rubber flexibility makes it ideal for Rochester’s subzero winters. It expands and contracts easily without cracking or tearing.

- Snow & Ice Load: Both TPO and EPDM perform well if drainage systems are properly designed. Standing water, not material type, is the main cause of winter roof failure.

- Energy Efficiency: EPDM’s black surface helps retain heat during winter, while TPO reflects sunlight to reduce summer cooling costs — especially valuable for offices or retail spaces.

- Durability Under UV Exposure: Both membranes hold up well, but TPO’s bright surface can degrade if improperly formulated or installed by inexperienced contractors.

When EPDM Is the Better Choice

EPDM remains a reliable favorite for many Rochester businesses — especially for warehouses, manufacturing facilities, and older buildings with limited roof access. Choose EPDM when:

- You prioritize cold-weather flexibility and long-term durability.

- Your building operates year-round in a heating-dominant climate.

- You want a lower-cost system that’s easy to maintain and repair.

- You’re working with an older roof deck that benefits from a lighter, more forgiving system.

EPDM’s track record in northern climates makes it one of the most dependable systems available for commercial roofing in Rochester.

When TPO May Be the Smarter Investment

TPO’s popularity has surged in recent years — and for good reason. It combines durability with energy efficiency, and it’s a strong option for buildings seeking modern performance and sustainability. TPO is ideal when:

- Your building experiences high summer cooling demands.

- You want to reduce heat absorption and energy costs with a reflective surface.

- Your roof sees moderate foot traffic and requires strong seam strength against moisture intrusion.

- You’re investing in a new commercial construction project that prioritizes aesthetics and efficiency.

In short: TPO often shines on newer buildings, retail plazas, and office spaces where energy savings and a clean, bright appearance are top priorities.

Installation Quality Matters More Than Material Type

Even the best roofing material will fail if it’s not installed correctly. That’s why choosing an experienced commercial roofing contractor is critical. Poor seam welding, inadequate drainage, or insulation issues can reduce lifespan and lead to premature leaks.

At Sunset Roofing, we use certified installation practices and partner with trusted manufacturers to ensure your roof performs as promised. Every project includes thorough inspections, attention to detail, and long-term maintenance recommendations customized to your building.

Maintenance Tips for Long-Term Performance

Both TPO and EPDM require routine maintenance to maximize lifespan. We recommend:

- Scheduling biannual inspections — in spring and fall — to identify small issues early.

- Keeping drains and scuppers clear to prevent standing water.

- Repairing punctures and seams promptly to prevent moisture infiltration.

- Documenting every inspection and service visit for warranty compliance.

Routine maintenance not only extends your roof’s life but also helps preserve manufacturer warranties and prevent costly downtime.

Which Roof Is Right for Rochester Businesses?

When deciding between TPO and EPDM, consider your building’s specific needs, energy profile, and long-term maintenance goals. There’s no one-size-fits-all solution, but here’s a simplified way to think about it:

- Choose EPDM for proven cold-weather performance, reliability, and budget-friendly installation.

- Choose TPO for energy efficiency, modern performance, and durable, heat-welded seams.

Both systems can deliver decades of protection when installed and maintained by the right roofing team.

Protect Your Investment with Sunset Roofing

Whether you need a full roof replacement or want to explore which material offers the best ROI for your property, Sunset Roofing is your trusted partner for commercial roofing in Rochester, NY. Our team provides transparent assessments, expert installation, and maintenance programs designed to extend the life of your roof and protect your operations year-round.

Call 585-538-6086 or contact Sunset Roofing today to schedule a commercial roof consultation. We’ll help you choose the right system — and make sure it’s installed to perform through every Rochester season.

‹ Back